Industrial field

Industrial production is crucial to the development of the national economy, but industrial production will produce a large amount of industrial sewage. If the industrial sewage is not treated, it will seriously affect the social environment. Industrial water treatment is to treat water quality to meet the water quality requirements of different processes and equipment within the enterprise, ensuring the normal production of the enterprise. Today's industrial enterprises attach great importance to water quality and corresponding water treatment work, because it is an important condition for ensuring product quality, improving efficiency, and protecting equipment.

Application areas

life sciences

Process water, preparation water, washing water, water for injection, infusion, injection, tablet, biochemical products, sterile water equipment

food and drink

Formula water, production water, washing water, beer, liquor and other alcoholic beverages, drinking mineral water, purified water

Power Electronics

Boiler feed water, cooling water, demineralized water, chemicals, fine chemicals, cosmetics manufacturing and other process water

Petrochemical

Oilfield injection water, circulating water, petrochemical wastewater, oil-water separation, oil-soil separation

Sewage treatment field

Underground integrated sewage treatment, equipment container sewage treatment equipment, MBBR sewage treatment equipment

Desalination field

Drinking water for island residents, drinking water for coastal residents, offshore drilling platforms, warships, and ships

Aodlon Reverse Osmosis System

Reverse osmosis, also known as reverse osmosis, is a membrane separation operation that uses pressure difference as a driving force to separate solvent from a solution. When the pressure exceeds its osmotic pressure, the solvent will reverse osmosis in the direction of natural osmosis. The permeated solvent is obtained on the low-pressure side of the membrane, which is the permeate; the concentrated solution is obtained on the high-pressure side, which is the concentrated solution. If reverse osmosis is used to treat seawater, fresh water will be obtained on the low-pressure side of the membrane, and brine will be obtained on the high-pressure side.

Service areas

Preparation of pure water, distilled water, etc. • Use of water for alcoholic beverage manufacturing and decontamination • Boiler feed water desalination and soft water • Concentration, separation, purification and water distribution preparation of chemical processes • Desalination of sea water and brackish water • Preliminary use of water in medicine, electronics and other industries Preparation • Advanced treatment of urban sewage • Water and wastewater treatment in papermaking, electroplating, printing and dyeing, food and other industries

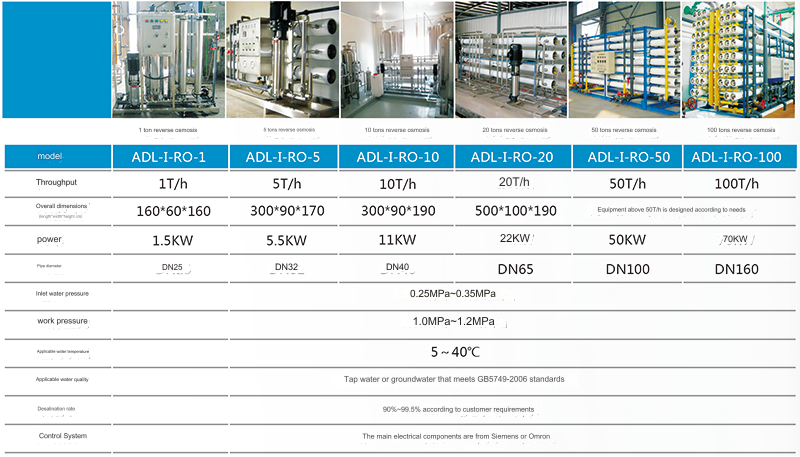

Conventional reverse osmosis equipment technical parameters

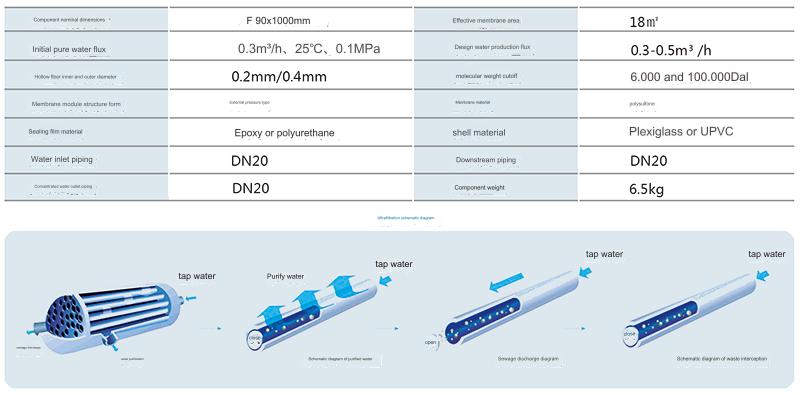

Aodlon Ultrafiltration System

Ultrafiltration technology is a membrane separation process that uses sieving as the separation principle and pressure as the driving force. The filtration precision is in the range of 0.005-0.01um, which can effectively remove particles, colloids, bacteria and polymer organic matter in water. It has good temperature resistance, acid and alkali resistance and oxidation resistance. Compared with other purification and separation devices, the Aodlon ultrafiltration system has four major advantages: high precision, long life, large throughput, and low cost.

Service areas

• Preliminary treatment of natural water purification and reverse osmosis systems: can reduce the turbidity of raw water to less than 1NTU, ensuring long-term stable water production and desalination rate of the reverse osmosis membrane • As the host part of mineral water equipment and mountain spring water equipment: filtration Suspended solids, organic matter, bacteria and other harmful substances as well as peculiar colors and odors, while retaining various trace elements and minerals in the water that are beneficial to human health. • Used for the separation, concentration and corrosion removal of pharmaceutical, chemical, beverage and other liquid materials. Household , drinking water purification for work units and residential areas: perform secondary treatment on tap water to make it clean, clear and transparent, and become healthy drinking water. • Aseptic liquid food manufacturing: remove corrosion and sterilization of low-alcohol liquor, make instant solution tea, Manufacturing of fruit wine, beer and other alcoholic beverages, etc.

Technical Parameter

Aodlon electrodeionization system

EDI is the abbreviation of Electrodeionization. It is a pure water manufacturing technology that combines ion exchange technology, ion exchange membrane technology and ion electromigration technology. Aodlon Company is the fluid processing technology and business partner and regional general agent of General Electric (GE) in the United States. The GE-EDI module used in the assembly of our company has the characteristics of high water production, stable water quality, strong performance controllability, and low energy Consumption characteristics.

Service areas

• Semiconductor and electronics industry - ultrapure water • Biological and pharmaceutical industry - purified water • Power plant - boiler feed water • Surface coating • Replacement of various types of distilled water • Consumer goods and cosmetics industry

Process flow

• Pretreatment----Re-bed----Mixed bed---Polishing resin

• Pretreatment----reverse osmosis---mixed bed---polishing resin

• Pretreatment----reverse osmosis----CEDI membrane block----polishing resin

Technical parameters

|

Model |

ADL-MK-2E |

ADL-MK-3 |

ADL-MK-2ST |

ADL-MK-2Mini |

|

Water production of a single module |

1.7-4.5m³/h |

1.7-4.54m³/h |

1.7-4.54m³/h |

1.7-4.5m³/h |

|

Rated recovery rate |

90-95% |

85-95% |

90-95% |

90-95% |

|

Range of working temperature |

4.4-38℃ |

4.4-40℃ |

4.4-40℃ |

4.4-40℃ |

|

Inlet water pressure |

3.1-6.9 bar |

3.4-6.9 bar |

3.1-6.9 bar |

3.1-6.9 bar |

|

Pressure drop between inlet and outlet water |

1.4-3.4bar |

1.4-2.8bar |

1.4-3.4bar |

1.4-3.4bar |

|

1. With CE, UL, CSA marks. |

||||

|

2. Made in an ISO9001:2015 certified factory. |

||||

Aodlon desalination system

Desalination is the use of seawater desalination to produce fresh water. It is an open source incremental technology to realize water resource utilization, which can increase the total amount of fresh water and is not affected by time, space and climate. Aodlon Company has rich experience in reverse osmosis seawater desalination technology. The reverse osmosis seawater desalination technology has developed rapidly, and the project cost and operating cost have continued to decrease.

Development Trend

• Reduce the operating pressure of the reverse osmosis membrane • Improve the recovery rate of the reverse osmosis system • Cheap and efficient pretreatment technology • Enhance the anti-pollution ability of the system

Features

• Can be operated at normal temperature (5-40℃), with excellent water production, low energy consumption and low cost

• Designed according to the particularity of the ship to achieve small size, light weight and easy installation

• The pretreatment device adopts multi-way valve technology to avoid frequent cleaning and environmental pollution

• Simple operation and maintenance, with electricity and sea water, and produces fresh water immediately after startup

Large seawater desalination equipment

Technical parameters

|

Model |

ADL-Fhs200 |

Water production (m³/d) |

5 |

|

Operating pressure(MPa) |

3.5~6.5 |

Electricity consumption per ton of water(KW·H) |

4 |

|

Freshwater production |

≥200L/H |

Desalination rate |

≥98.5% |

|

Recovery rate |

≥28% |

Operating pressure |

3.5~6.5MPa |

|

Power |

2KW |

Operating temperature |

5~40℃ |