The National Development and Reform Commission issued four interpretation articles in a row, and the water treatment membrane materials industry welcomes new developments

Recently, the National Development and Reform Commission issued four interpretation articles in a row to comprehensively interpret the "14th Five-Year Plan for Urban Sewage Treatment and Resource Utilization Development Plan" issued.

During the "14th Five-Year Plan" period, the utilization of sewage resources has been accelerated, which has promoted the empowerment and upgrading of the sewage treatment industry. Its key material, water treatment membrane, has also received more and more attention, which has also promoted the development of my country's water treatment membrane industry.

According to estimates, the total investment in my country's membrane recycled water treatment market will reach 107.1 billion yuan. As sewage resource utilization continues to accelerate, the market space of 100 billion yuan will accelerate.

Water treatment membranes are widely used and have many product types

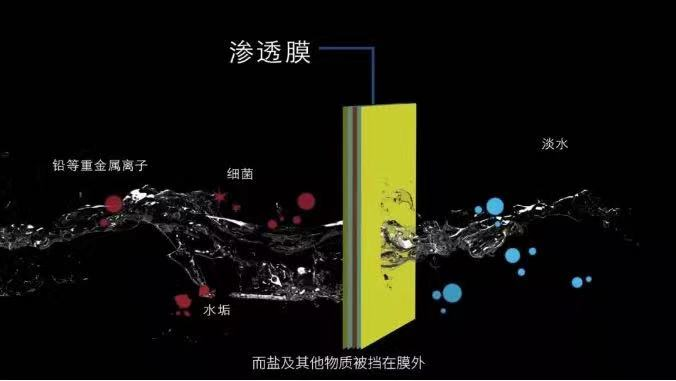

Water treatment membranes are widely used and have many product types. From the perspective of product type and technology, they can be divided into reverse osmosis membranes (RO), ultrafiltration membranes (UF), microfiltration membranes (MF), and nanofiltration membranes (NF). Microfiltration membranes are mainly used in sewage, wastewater treatment and other fields; ultrafiltration membranes are widely used in sewage, wastewater treatment and reuse and water purification fields; nanofiltration membranes are mainly used in pure water, softened water, ion-free water, and seawater desalination. etc.; reverse osmosis membranes can be used in fields such as seawater desalination.

Figure: Principle diagram of membrane water treatment. Source: Sinochem

According to different membrane materials, water treatment membranes are mainly divided into organic membranes and inorganic membranes. Commonly used filter membrane materials for organic membranes include cellulose acetate, polysulfone, polyethersulfone, polyethylene, polypropylene, polyacrylonitrile, and polyvinylidene fluoride. Ethylene (PVDF), polytetrafluoroethylene (PTFE), polyvinyl chloride (PVC), aromatic polyamide (PPTA), etc. and their modified materials. Among them, polytetrafluoroethylene material has good chemical stability, thermal stability and mechanical strength, and can be dissolved in a variety of solvents. It is one of the most widely used membrane materials currently.

Current status of global water treatment membrane materials market

In 2020, the global water treatment membrane materials market reached US$2967.57 million, and is expected to reach US$3901.93 million in 2027, with a compound annual growth rate (CAGR) of 3.22%.

The domestic water treatment membrane market is developing rapidly. The market size in 2020 was US$846.75 million, accounting for approximately 28.53% of the global market. It is expected to reach US$1,278.98 million in 2027, when the global share will reach 32.78%.

As the demand for seawater desalination, brackish water softening, ultrapure water preparation and the removal of trace pollutants increases year by year, the proportion of reverse osmosis membranes in the membrane market has also increased. QY Research data shows that reverse osmosis membranes account for 54.66% %, ultrafiltration membrane accounts for 26.02%, microfiltration membrane accounts for 16.14%, and nanofiltration membrane accounts for 3.18%. In the future, with the increasing demand for wastewater resource utilization and deep water treatment, the membrane industry will develop rapidly.

Figure 2020 global market share of water treatment membrane materials by product type Source: QYResearch

The industrial structure of my country's water treatment membranes is still unbalanced. The production technology of microfiltration membranes and ultrafiltration membranes is highly localized, and the product self-sufficiency rate is about 85%. There is overcapacity in mid- to low-end products such as reverse osmosis membranes and nanofiltration membranes. High-end reverse osmosis membranes for industrial use still mainly rely on imports. The process of localization of technology is slow, and the product self-sufficiency rate is only about 50%.

Foreign companies occupy the main high-end product market

Foreign companies have developed water treatment membrane materials earlier and have relatively advanced technologies. Among them, the United States, Japan and other countries are the main ones, and they have almost a monopoly on the global high-end membrane material market.

At present, the international giants of membrane materials are mainly companies such as Dow Chemical, Nitto Denko, Toray, and GE. They have formed the first international echelon of membrane materials brands, accounting for more than 80% of the global market share. Among them, Dow Chemical of the United States is the The world's leading supplier and innovative company. In 2017, Dow and DuPont merged. The two parties merged and reorganized in the field of specialty chemicals and chemical materials (including membrane fields), further strengthening their strength and becoming the absolute leading company in the field of membrane materials, accounting for 35% of the world's total. above market share.

Dow Chemical Company has successively acquired FilmTec Company of Polaris Research Institute and Zhejiang European and American Environmental Engineering Co., Ltd., and has mastered core technologies such as ultrafiltration, membrane bioreactors and continuous electric desalination in the field of water treatment membranes. Dow Chemical also produces membrane materials business ventures into water treatment system manufacturers.

Relying on its advanced chemical material technology, Toray Group took the lead in developing high-performance membranes in the world, and also built the world's first mass-produced RO membrane factory. Currently, in addition to RO membranes, Toray also has UF membranes and MF membranes. , MBR and other all types of water treatment membranes, occupying an important position in the international water treatment membrane market. On June 17, 2021, Toray Water Treatment Membrane Project (Phase II) was signed in Foshan.

China has become the main market for RO membranes, and import substitution is the right time.

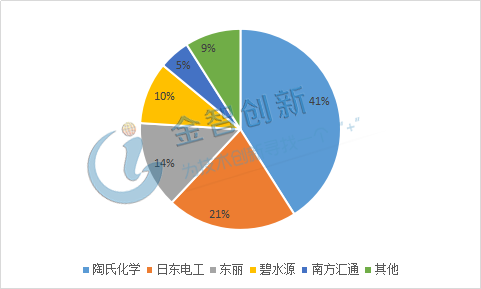

At present, my country's high-end water treatment membrane materials are occupied by leading international companies such as Dow, Toray, and Nitto Denko, accounting for more than 80% of the market share. Chinese companies use Southern Huitong and Bishuiyuan as the first-tier domestic brands, mainly occupying the market share in China. In the low-end market, with the continuous research and development and research on water treatment membrane technology in my country in recent years, Chinese companies are gradually penetrating from the low-end to the high-end.

Figure: Market situation of water treatment membrane materials in my country Source: Jinzhi Innovation Industry Research Center

At present, the total sales of RO membrane products in the Chinese market account for approximately 30%-35% of global sales, and the market size ranks first in the world.

Foreign RO membrane products dominate the market, among which Dow Chemical of the United States, Toray of Japan, and HydraNeng occupy about 70% of the market share.

Domestic RO membrane manufacturers are catching up, such as Guiyang Times Wharton. In addition, domestic membrane companies such as Blue Star (Hangzhou), Hunan Qinsen, Shandong Jiuzhang, Hunan Aowei, Bishuiyuan, Sinochem International, and Wanhua Chemical have begun to complete and put into production. , entering the RO market, it is expected that the localization rate of domestic RO membranes will improve significantly in the next 3-5 years.

Drawing on overseas development experience, my country's membrane companies still have a lot of room for improvement in production technology and material research and development, and membrane companies will still need to make continuous R&D investment in the future.

Large chemical companies have inherent advantages in the research and development of high-end membrane materials. In 2019, Wanhua Chemical invested 510 million yuan to establish a membrane factory project in Wanhua Industrial Park, with a total production capacity of 6.19 million square meters per year, including RO membrane: 3 million Square meters/year; NF membrane: 600,000 square meters/year; UF membrane: 500,000 square meters/year; Hollow fiber membrane: 1 million square meters/year; MF membrane: 1 million square meters/year; Modified separation membrane :90,000 square meters/year. Sinochem International invested approximately 970 million yuan to build a reverse osmosis membrane factory with an annual output of 220,000 units in Ningbo Xiangshan Economic Development Zone.

Conclusion

my country's water treatment membrane market is huge, and as environmental protection policies continue to become stricter, its market potential is gradually released, and the future prospects are good. At present, my country's high-end water treatment membrane products are mainly occupied by foreign companies, and domestic companies mainly occupy the mid-to-low-end product field. In the future, with the continuous strengthening of technology research and development, Chinese companies are expected to enter the high-end product field, break foreign monopoly, and achieve domestic substitution.

Recommended Posts

-

In recent years, the hygienic condition of dental unit waterline (DUWL) has gradually received attention in China. At the same time, many local standards have been introduced. For example, Beijing issued "DB11/T 1703- 2019 Technical Specifications for Waterway Disinfection of Oral Comprehensive Treatment Units" on December 25th, 2019, while Zhejiang Province issued "DB33/T 2307-2021 Technical Specifications for Cleaning and Disinfection of Dental Waterway Systems" on January 29, 2021. In fact, various countries in the world have begun to pay attention to issues related to waterway pollution in dental treatment units much earlier, and have made relevant specifications. This article summarizes the standards of various countries in this regard as follows: Foreign standards related to the waterway of dental treatment units In 1996, the American De...

comment